The traditional steel pallets rust and deform, with an annual replacement cost as high as 1 million dollars?

Did the fuel cost increase by 15% during transportation due to overweight pallets?

Were export goods detained due to quarantine issues with wooden pallets?

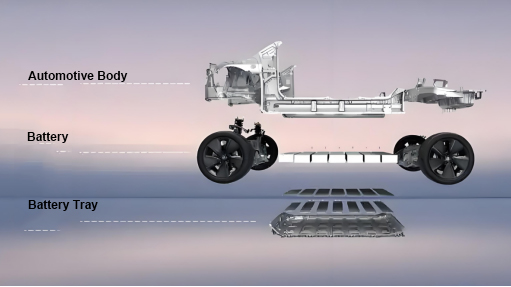

Solution: Special aluminum profile pallets for automobiles

Lightweight king: With a density only one-third that of steel, it can carry 20% more components in a single vehicle;

Never rusts: anodized treatment, salt spray test over 3000 hours;

Intelligent adaptation: Modular design compatible with mainstream car production lines such as Volkswagen/Toyota;

Environmental pass: 100% recyclable, in compliance with the EUREACH regulation.

Customer Feedback

After adoption by a certain German automotive group, it was achieved:

Logistics costs have dropped by 28%

The service life of the pallet has been extended to 10 years

The efficiency of export customs clearance has increased by 40%

Services provided by us:

① Relevant mold references are currently available

② Free CAD design drawings

③Free samples are available for quality inspection

What are the model classifications of aluminum profile pallets?

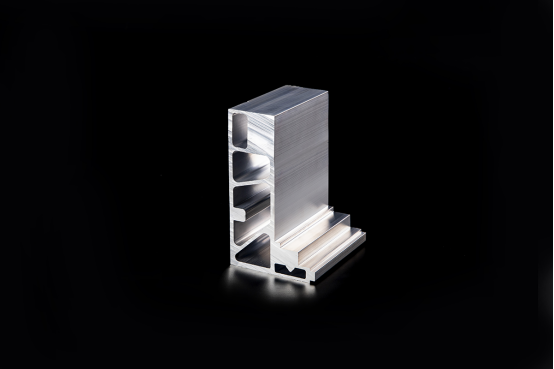

I. Classification by cross-sectional shape

Square tube pallet

Model: 20×20mm (light), 40×40mm (standard), 50×50mm (heavy)

Application:Turnover of small automotive parts, static load ≤300kg

Rectangular tube tray

Model: 20×40mm, 30×60mm, 50×100mm (super heavy duty)

Features: Bending strength increased by 40%, suitable for engine/transmission transportation

Slot aluminum tray

Model: 30×30mm, 40×40mm (European standard slot 8mm)

Advantage: The embedded forklift slot design increases loading and unloading efficiency by 50%

I-shaped aluminum pallet

Model: 50×30mm, 100×50mm (H-type structure)

Load-bearing capacity: Dynamic load ≥1.5 tons, used for battery pack transportation

II. Classification by international standards

European standard pallet (EN 71-3 certified)

Model section dimensions, slot width, typical load-bearing capacity

QY-8-8080A 80×80mm 8mm 800kg

QY-10-8080B 80×80mm 10mm 1.2 tons

Qy-8-80 160 80×160mm 8mm 2.5 tons

National standard pallet (GB/T 6892 standard)

Light-load series: 4040G (4mm wall thickness, 500kg)

Heavy-duty series: 8080GR (6mm wall thickness, 1.8 tons)

Special model: 100×100mm (3-ton aviation parts pallet)

III. Special Model cases

Battery tray (Tesla solution)

Model: 1.5mm ultra-thin wall one-piece molding

Technology: Integrated design of liquid cooling channels, reducing weight by 20kg per pallet

Export quarantine pallets (BYD solution)

Model: anodized 6061-T6

Certification: REACH regulation +100% fumigation-free

High-temperature environment tray (Indian case)

Model: 7075 alloy + nano-ceramic coating

Tolerance to 55℃ high temperature +5000 hours of salt spray

In conclusion, aluminum profile pallets, with their advantages such as lightweight, high strength, corrosion resistance and modular design, have become core logistics carriers in fields like automotive manufacturing and new energy battery transportation. From Tesla’s battery tray lightweight solution to BYD’s export compliance design, from Bosch’s intelligent production line transformation to Jianghuai’s recycled aluminum recycling application, benchmark cases in various industries have fully verified the outstanding value of aluminum profile pallets in improving efficiency, reducing costs and achieving sustainable development. By choosing the appropriate model and process (such as the European standard QY series, the national standard 8080GR type or customized solutions for special alloys), the load-bearing requirements and regulatory demands in different scenarios can be maximally met. In the future, with the development of green logistics and intelligent manufacturing, aluminum profile pallets will continue to drive the transformation and upgrading of the global supply chain.

Company website: www.aluminum-artist.com

Address: Pingguo Industrail Zone, Baise City, Guangxi, China

Email: info@aluminum-artist.com

Phone: +86 13556890771

Post time: Jul-05-2025