Ruiqifeng Factory Overview-Process Flow of Aluminium Products

1.Melting&Casting Workshop

Our own melting and casting workshop can realize waste recycling and reuse, control production costs, and improve production efficiency.

2. Mould Design Center

Our design engineers are ready to develop the most cost-effective and optimal design for your product, using our custom-made dies.

3. Extruding Center

Our extrusion equipment includes 600, 800T, 1000T, 1350T, 1500T, 2600T, and 5000T extrusion models of different tonnages, equipped with American-made Granco Clark (Granco Clark) tractor, which can produce the largest circumscribed circle Various high-precision profiles up to 510mm.

5000Ton Extruder

Extruding Workshop

Extruding Profile

4. Aging furnace

The main purpose of the aging furnace is to remove stress from the aging treatment of aluminum alloy and stainless steel stamping parts. It can also be used for drying ordinary products.

5. Powder Coating Workshop

Ruiqifeng possessed two horizontal powder coating lines and two vertical powder coating lines which used Japanese Ransburg fluorocarbon PVDF spraying equipment and Swiss(Gema) powder spraying equipment.

Powder Coating Workshop overview

Horizontal powdercoating line

Vertical powder coating line-1

Vertical powder coating line-2

6. Anodizing Workshop

Possesses advanced oxygenation& electrophoresis production lines, and can produce oxygenation, electrophoresis, polishing, and other series products.

Anodizing for building profiles

Anodizing for heatsink

Anodizing for Industrial Aluminium Profiles-1

Anodizing for Industrial Aluminium Profiles-2

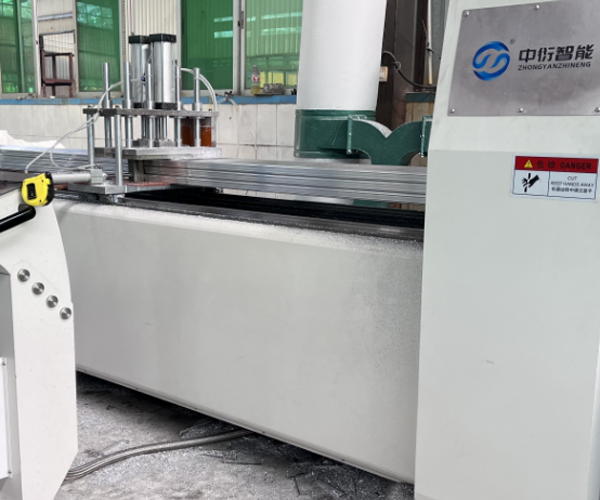

7. Saw Cut Center

The sawing equipment is fully automatic and high-precision sawing equipment. The sawing length can be adjusted freely, the feeding speed is fast, the sawing is stable, and the precision is high. It can meet the customers' sawing requirements of different lengths and sizes.

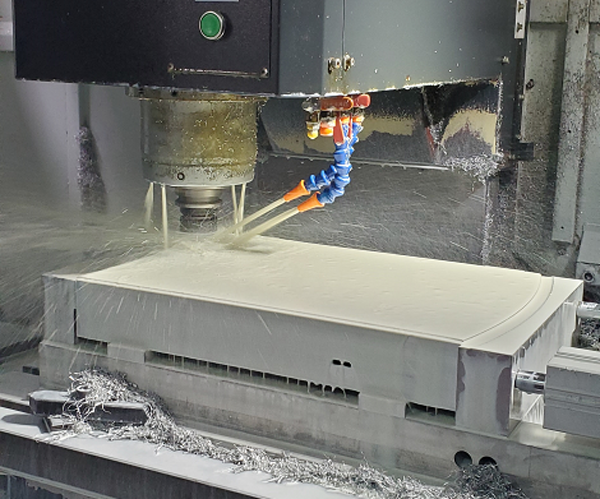

8. CNC Deep Processing

There are 18 sets of CNC machining center equipment, which can process parts of 1000*550*500mm (length*width*height). The machining accuracy of the equipment can reach 0.02mm, and the fixtures use pneumatic fixtures to quickly replace products and improve the actual and effective running time of the equipment.

CNC Equipment

CNC Equipment

Finish products

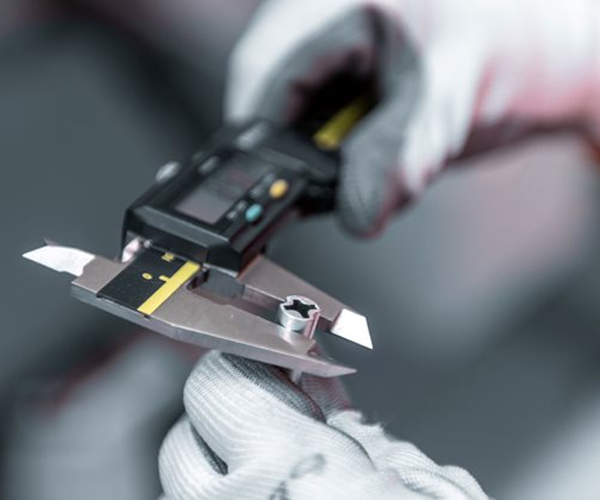

9. Quality control -Physical Testing

We have not only manual inspection by QC personnel, but also an Automatic Optical Image Coordinate Measuring Machine measuring instrument to detect the cross-sectional area size of the heatsinks, and a 3D coordinate measuring instrument for three-dimensional inspection of the product's all-round dimensions.

Manual testing

Automatic Optical Image Coordinate Measuring Machine

3D Measuring Machine

10.Quality control-Chemical Composition Test

Chemical composition and concentration test-1

Chemical composition and concentration test-2

Spectrum analyzer

11. Quality control-Experiment and testing equipment

Salt spray test

Size scanner

Tensile test

Constant temperature and humidity

12. Packing

13. Loading & Shipment

Logistic Supply-Chain

Convenient transportation network by sea, land and air