Do You Know the Application and Difference between aluminium 6005, 6063 and 6065?

Aluminum alloys are widely used in various industries due to their excellent properties such as lightweight, corrosion resistance, and malleability. Among the different aluminum alloys, 6005, 6063, and 6065 are popular choices for extrusion and structural applications. Understanding their differences and applications is crucial for selecting the most suitable alloy for specific needs.

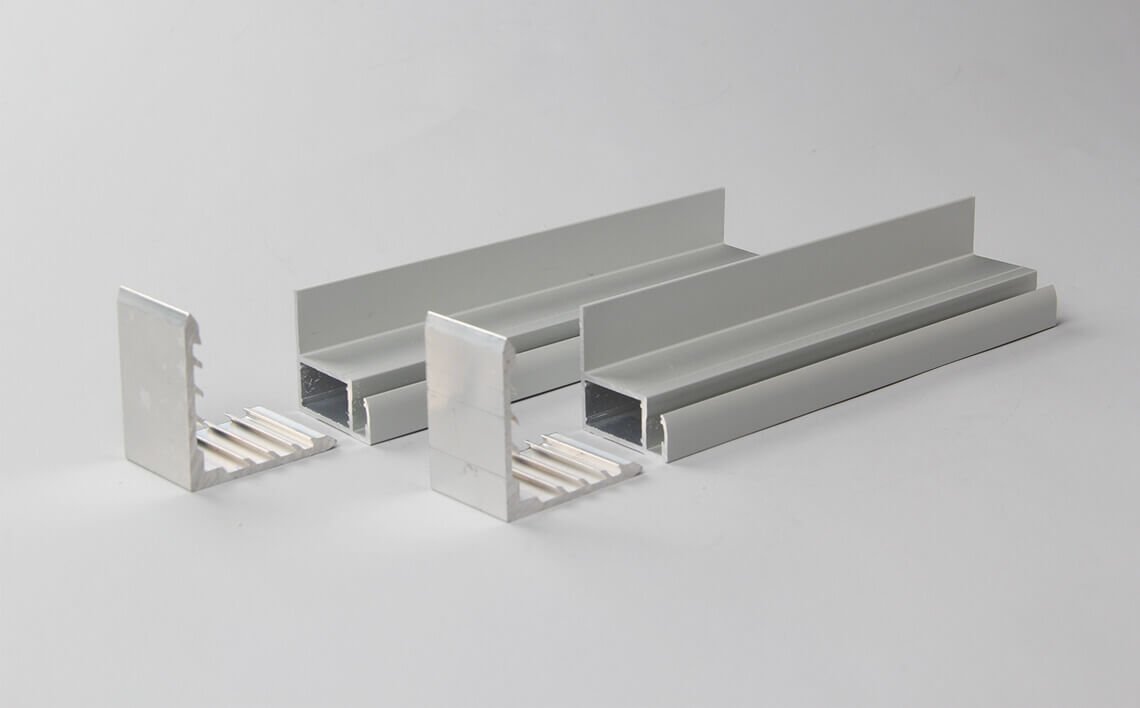

Aluminum Alloy 6005: Alloy 6005 is a medium-strength aluminum alloy with good extrudability and mechanical properties. It is known for its high strength, making it ideal for structural applications. The alloy offers excellent corrosion resistance and anodizing characteristics, making it suitable for architectural and building applications. Common uses of 6005 aluminum include structural members, architectural trim, and various extruded components requiring strength and corrosion resistance, such as solar module frame.

Aluminum Alloy 6063: Alloy 6063 is another popular aluminum alloy widely used for extrusion and architectural purposes. It is valued for its good formability, surface finish, and corrosion resistance. 6063 aluminum is commonly employed in window frames, door frames, and various architectural and decorative applications. While 6063 offers moderate strength, its excellent formability and aesthetic appeal make it a preferred choice for a wide range of architectural and extruded profiles.

Aluminum Alloy 6065: Alloy 6065, while not as commonly used as 6005 and 6063, shares similarities with both alloys. It exhibits good extrudability and is suitable for structural and architectural applications. In addition, 6065 aluminum provides a balance of strength and formability, making it suitable for applications that require a combination of these properties. Its use may include structural components such as aluminium mounting system, architectural trim, and customized extruded profiles where a specific balance of strength and formability is needed.

Understanding the differences between aluminum alloys 6005, 6063, and 6065 allows for informed decision-making when selecting the most suitable material for a given application. While 6005 offers higher strength and good corrosion resistance, 6063 stands out for its excellent formability and surface finish. Alloy 6065 provides a balance of strength and formability, making it a versatile choice for specific applications.

In conclusion, the selection of the appropriate aluminum alloy should be based on the specific requirements of the intended application. Factors such as strength, formability, corrosion resistance, and extrudability play a crucial role in determining the most suitable alloy for a particular use. Consulting with material experts or suppliers can provide valuable insights into the properties and applications of aluminum alloys, helping to ensure the optimal selection for various extrusion and structural needs.

Post time: Jan-03-2024