Aluminum extrusion is a highly efficient and versatile manufacturing process used to create components with specific cross-sectional profiles. At the heart of this process lies one of the most vital elements: the extrusion die. This precision-engineered tool shapes aluminum under immense pressure and plays a pivotal role in determining product quality, surface finish, and dimensional accuracy.

What Is an Aluminum Extrusion Die?

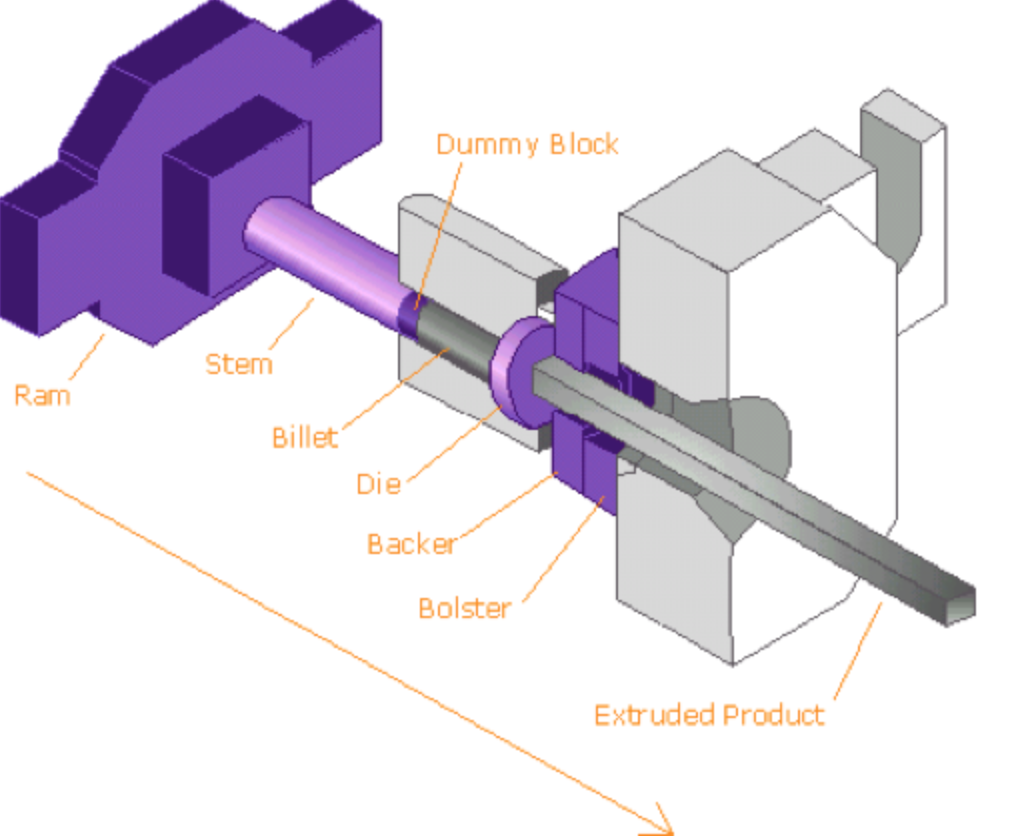

An extrusion die is a specially designed steel tool with a specific die opening that shapes the aluminum as it is forced through under high pressure. Along with support tools such as backers, bolsters, and sub-bolsters, the die ensures proper alignment and structural integrity during extrusion.

Types of Extrusion Dies

Extrusion dies are categorized into three main types based on the desired profile geometry:

1. Solid Dies

Used for producing profiles without any cavities — such as bars, angles, or channels.

-

Components:

-

Die Plate: Contains the shaped orifice for the final profile.

-

Backer Plate: Provides support behind the die.

-

Feeder Plate (optional): Assists in guiding material flow.

-

2. Hollow Dies

Designed for profiles with internal voids like tubes or window frames.

-

Components:

-

Mandrel (or core): Forms the internal cavity.

-

Die Cap: Forms the outer shape and holds the mandrel in place.

-

Backer: Provides structural support and heat management.

-

3. Semi-Hollow Dies

Used for profiles with partially enclosed voids — combining features of solid and hollow sections. These are ideal for complex geometries with variable wall thicknesses.

The Extrusion Process and the Die’s Function

Key extrusion steps include:

-

Billet Preheating:

Aluminum billets are preheated to 370–500°C (700–930°F) to improve plasticity. -

Loading & Extrusion:

The billet is loaded into the container, and a hydraulic ram (with pressure from 1,000 to 15,000 tons) pushes it through the die. -

Profile Formation:

The aluminum takes the shape of the die opening as it exits, forming the required profile. -

Cooling, Cutting & Finishing:

Profiles are cooled, stretched, cut to length, and may undergo surface finishing like anodizing or powder coating.

Throughout this process, the die ensures shape precision, surface quality, and consistency.

Die-Related Tolerances and Wall Thickness Control

Precision is crucial. Aluminum extrusion tolerances depend on:

-

Profile size & complexity

-

Wall thickness (very thin walls increase difficulty)

-

Die wear over time

Wall thickness can vary slightly, especially on new dies — initial extrusions might be slightly thinner, but with use, dies stabilize and better conform to the nominal design. This is why subsequent batches often show slightly thicker and more consistent results.

Common tolerances are governed by international standards such as EN 755-9 or AA (Aluminum Association) specifications.

Die Surface Treatments and Maintenance

To improve performance and lifespan, extrusion dies often undergo:

Nitriding

A surface hardening process that diffuses nitrogen into the die surface, increasing hardness and wear resistance — essential for handling high pressure and temperature.

Die Preheating (Die Cooking)

Also known as “煲模 (bao mo)” in Chinese, this practice gradually heats the die before extrusion to reduce thermal shock and improve metal flow consistency.

Common Die Challenges and Preventive Practices

Wear and Tear

High pressure and temperature cause gradual wear. Regular inspection, re-polishing, and re-nitriding extend die life.

Surface Defects

Scratches, die lines, or buildup can affect surface quality. Routine die cleaning and surface treatments help reduce defects.

Thermal Management

Uneven heating or cooling leads to defects or die breakage. Proper insulation and controlled preheating are critical.

Alignment and Support

Poor alignment causes dimensional errors and early die failure. Periodic re-calibration and maintenance are essential for precision.

Why Dies Matter in Aluminum Extrusion

A well-designed, well-maintained extrusion die directly impacts:

-

Dimensional accuracy

-

Profile complexity

-

Extrusion speed

-

Surface finish

-

Overall product cost and consistency

Choosing the right die type, understanding wall thickness management, and implementing strong preventive maintenance practices are essential to achieving consistent, high-quality results.

Looking for a Reliable Custom Die & Extrusion Partner?

At Ruiqifeng, we specialize in precision aluminum extrusion and offer full support for custom die development, profile optimization, and die life-cycle management. Whether you’re producing solid, hollow, or complex hybrid profiles, our engineering team is ready to assist with expert insights and dependable manufacturing.

Contact us today to learn more about how we can bring your designs to life with the right extrusion solutions.

Post time: Jun-13-2025