After aluminum alloy is made into aluminum ingot, it goes through three stages to become radiator:

1. The extruder made the ingot into aluminum extruded bar, processing as below :

a. The aluminum ingot is fed into the aluminum mold machine, heated to 500°C and thrust through the aluminum extrusion die (also heated to 380°C to avoid mold deformation).

b. Tempo or Aging treatment, increase hardness for easy subsequent cutting & processing; Aging treatment requires roasting at 185°C for 6 hours (3.5 hours at 190°C, 2 hours and 20 minutes at 200°C)

c. Cooling, cutting (5~6 meters per unit), inspecting, packaging and warehousing or transporting.

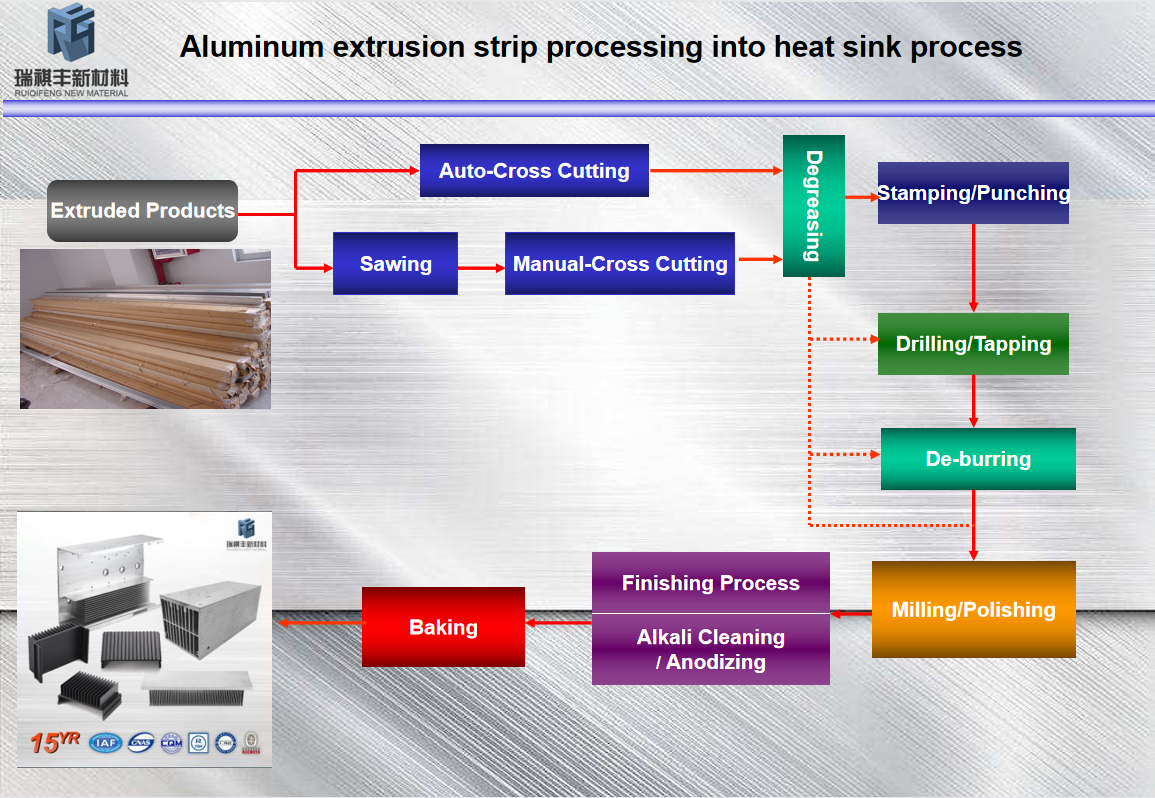

2. Aluminum extruded strip is processed into heat sink

3. Processed heat sink and fan… Etc., assembled into a radiator

Post time: May-05-2022