Aluminum is the second-most abundant metallic element on Earth after silicon, while steel is the most widely used alloy worldwide. While both metals have a wide range of applications, there are several crucial factors that can assist in determining which one is most suitable for the specific task at hand. Let’s go into these two metals:

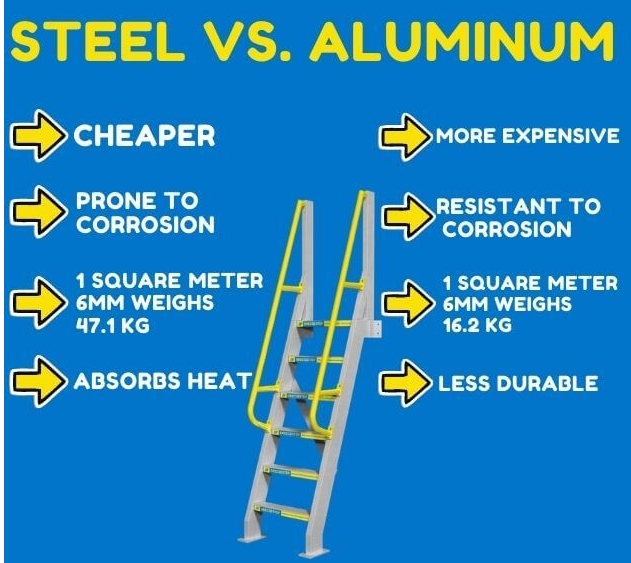

RUST RESISTANCE

Aluminum undergoes oxidation, similar to the chemical reaction that causes iron to rust. However, unlike iron oxide, aluminum oxide adheres to the metal, providing protection from decay without the need for additional coatings.

Steel, specifically carbon (non-stainless) steel, usually requires painting after processing to shield it from rust and corrosion. Corrosion protection for steel can be achieved through processes such as galvanization, often involving the use of zinc.

FLEXIBILITY

While steel is renowned for its durability and resilience, aluminum exhibits greater flexibility and elasticity. Thanks to its malleability and smooth fabrication, aluminum can be formed into intricate and precise spinning, offering significant design versatility. In contrast, steel is more rigid and may crack or tear when subjected to excessive force during the spinning process.

STRENGTH

Despite being susceptible to corrosion, steel is harder than aluminum. While aluminum does gain strength in colder environments, it is more prone to dents and scratches compared to steel. Steel is more resistant to warping or bending from weight, force, or heat, making it one of the most durable industrial materials.

WEIGHT

Steel’s superior strength also comes with a higher density, being 2.5 times that of aluminum. Despite its weight, steel is approximately 60 percent lighter than concrete, making it easier to transport and use in various construction and fabrication applications. However, when shape and structural rigidity are optimized, aluminum can provide similar reliability to a comparable steel structure at half the weight. For instance, in boat building, the rule of thumb is that aluminum is roughly half the strength of steel at one-third the weight, allowing for an aluminum vessel to be built with two-thirds the weight of a comparable steel boat at a given strength.

COST

The cost of aluminum and steel fluctuates based on global supply and demand, related fuel costs, and the iron and bauxite ore market. Generally, a pound of steel is cheaper than a pound of aluminum.

Which Metals is better?

Like we mentioned previously, while steel typically costs less per pound than aluminum, the best metal for a particular job ultimately depends on the specific application. It’s important to consider the qualities of each metal as well as the cost when selecting the most suitable metal for your upcoming project.

Ruiqifeng brings 20 years of expertise in the field of aluminum extrusion products. Should you require further information about aluminum products, please don’t hesitate to get in touch with us.

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Post time: Dec-12-2023