Do You know the Effects of Alloying Elements?

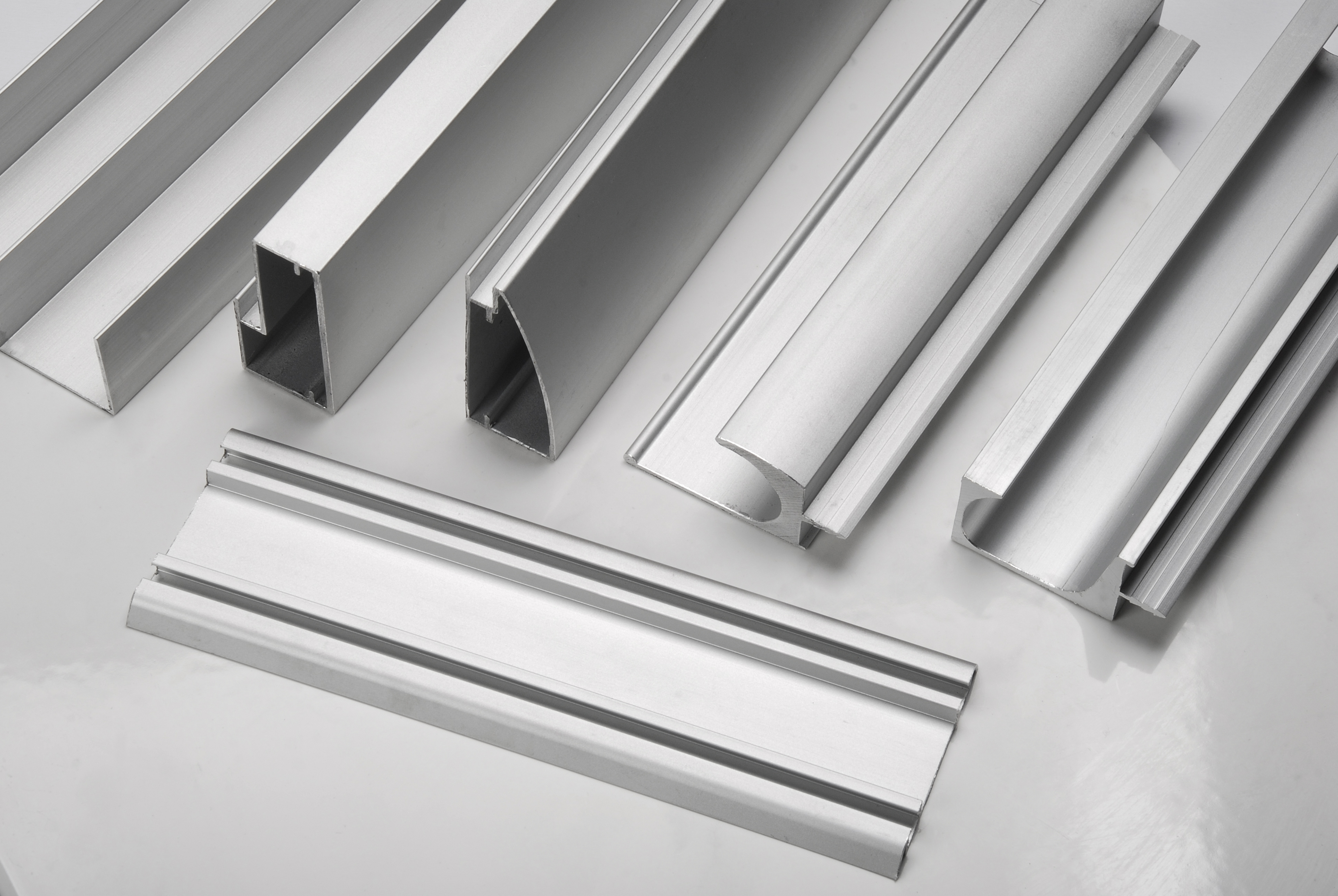

The properties and characteristics of aluminum, such as density, conductivity, corrosion resistance, finish, mechanical properties, and thermal expansion, are modified by the addition of alloying elements. The resulting effect depends upon the principal alloying elements used, as detailed in the table below.

Wrought Alloy Designation |

Major Alloying Elements and Typical Alloy Characteristics |

1000 Series |

Minimum 99% aluminumHigh corrosion resistance. Excellent finishability. Easily joined by all methods. Low strength. Poor machinability. Excellent workability. High electrical and thermal conductivity. |

2000 Series |

CopperHigh strength. Relatively low corrosion resistance. Excellent machinability. Heat treatable. |

3000 Series |

ManganeseLow to medium strength. Good corrosion resistance. Poor machinability. Good workability. |

4000 Series |

SiliconNot available as extruded products. |

5000 Series |

MagnesiumLow to moderate strength. Excellent marine corrosion resistance. Very good weldability. |

6000 Series |

Magnesium & SiliconMost popular extrusion alloy class. Good extrudability. Good strength. Good corrosion resistance. Good machinability. Good weldability. Good formability. Heat treatable. |

7000 Series |

ZincVery high strength. Good machinability. Heat treatable. |

Any requirment and inquiries for aluminum alloy, please contact Rui Qifeng.

Guangxi Rui QiFeng New Material Co., Ltd.

Address: Pingguo Industrial Zone, Baise City, Guangxi, China

Email : Jenny.xiao@aluminum-artist.com

Post time: Feb-23-2023