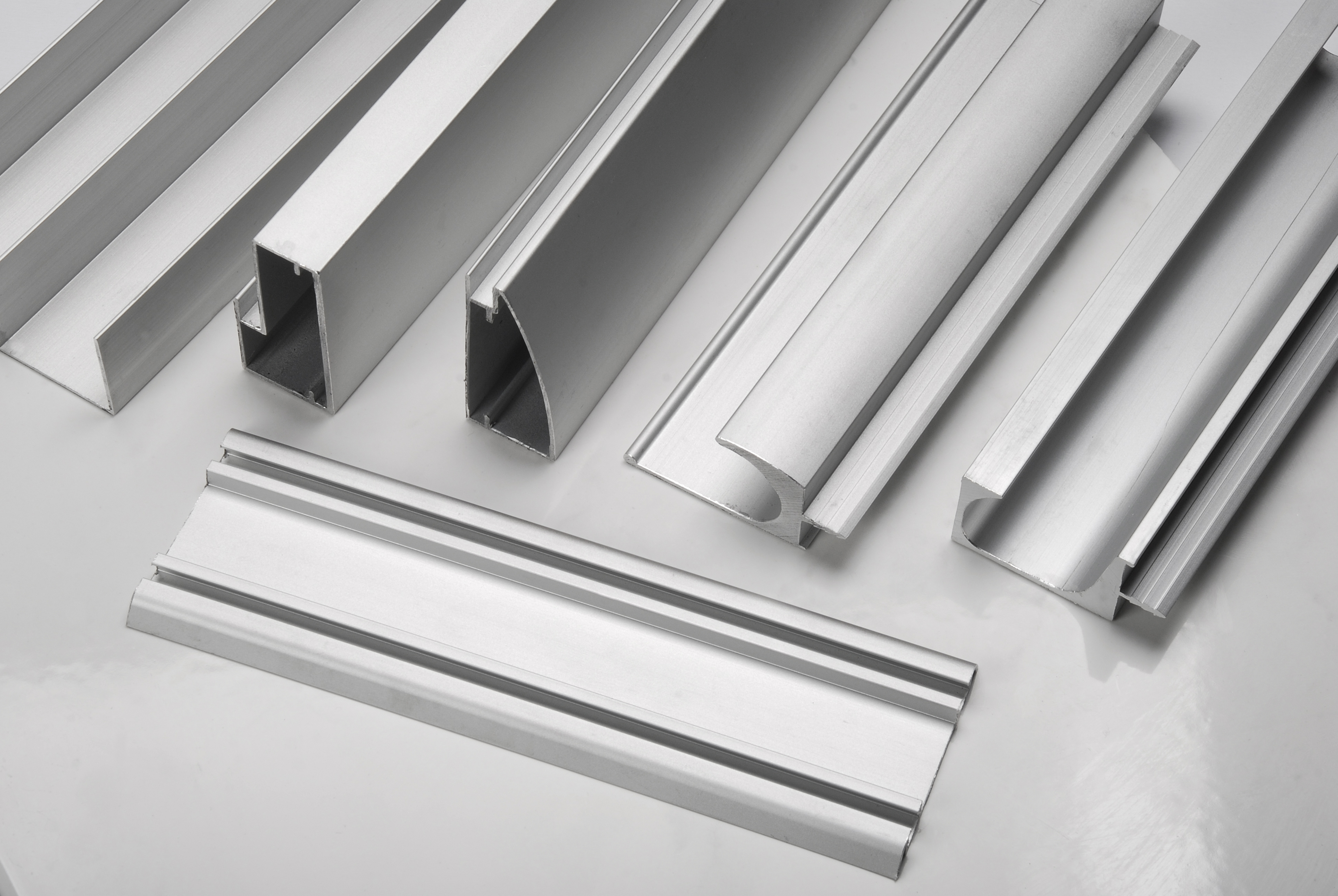

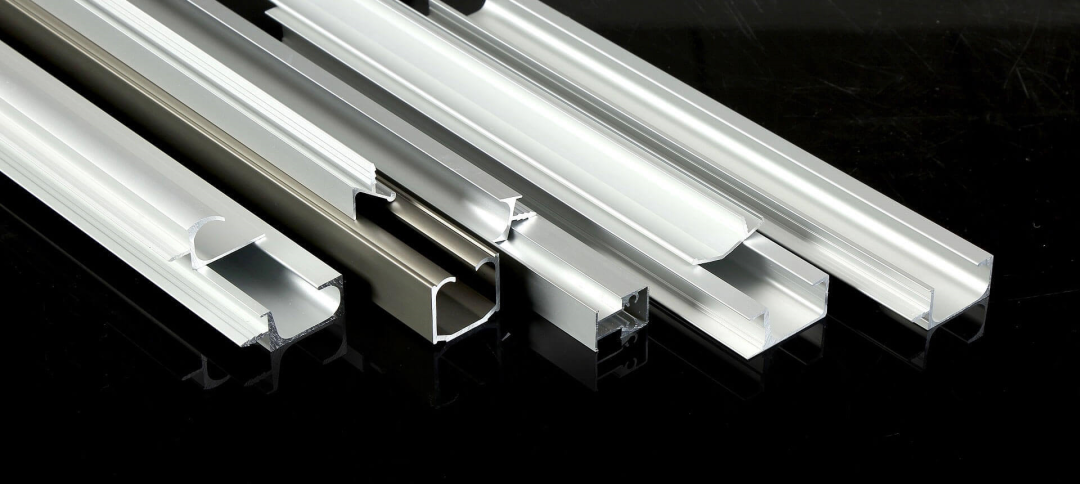

Aluminum is an important basic material. In daily life, we can often see the use of aluminum profiles in building doors, windows, curtain walls, indoor and outdoor decorations and building structures.

Architectural aluminum profiles have specific requirements for standardization and mass production, and the aluminum rod extrusion process is usually used to achieve an optimized solution for production and manufacturing. The basic idea of aluminum profile extrusion is to apply a certain pressure on the aluminum rod in the extrusion barrel to make the aluminum alloy flow out of a specific die hole, thereby obtaining aluminum profiles of specific shapes and sizes. This extrusion processing method has low cost, high efficiency and simple operation, and occupies a considerable proportion in the modern industrial production system. This article will focus on the extrusion production process of aluminum profiles, allowing us to have a deeper understanding of aluminum profile products:

1. Production of raw materials

According to the calculated composition ratio of the required aluminum profiles, various raw materials are reasonably equipped.The aluminum ingot is heated to a certain temperature for melting, and a certain amount of alloying elements are added to the molten aluminum liquid (magnesium and silicon are usually added to system door and window product lines). The slag and waste gas in the melt are removed by corresponding refining means.Under the qualified casting process conditions, the melted aluminum liquid is poured into the casting machine, cooled and cast into round cast rods with diameters and specifications that meet the expectations.

①Place the aluminum rods flat on the material rack, avoid being too close to each other or stack them, and reserve a safe operation space to prevent the aluminum rods from rolling or even falling.

②Heat the aluminum rod and mold in the furnace to raise the temperature to 480°C, and keep it warm for 1 hour before subsequent processing;

③Place the mold in the die base of the extruder, put the aluminum rod into the feed port of the extruder and prepare for extrusion;

④The extruded profile comes out of the discharge hole, and the material head is pulled by the tractor, and the preliminary cutting is carried out according to the set length and size.

3. Straightening

Aluminum profiles drawn by extrusion usually do not meet the straightness standards, which affects subsequent use or operation on mechanical equipment.The extruded aluminum profiles are sent to the straightening table for straightening, and then transported to the finished product area for cutting to length.

4. Timeliness treatment

Putting the aluminum alloy profile material into the aging furnace to heat it to a certain temperature and keeping it warm for 2-3 hours can significantly improve the mechanical properties of the aluminum alloy profile, especially the hardness properties.Put the cut aluminum profiles into the material frame, transport them to the aging area, and enter the aging furnace for manual aging treatment. When the aging temperature reaches 200℃, keep it warm for 2 hours, and then wait for it to be released;After the aging is completed, it can be taken out of the oven and enter the cooling stage. It can be cooled naturally or artificially with an air cooler.At this point, the extrusion work ends, and the extrusion of aluminum profiles with qualified appearance quality and shape and size is completed.

5. Surface treatment

Apply appropriate surface treatment as needed. Currently, there are several popular surface treatment processes in the system door and window industry: anodizing, electrophoresis, porcelain coating, fluorocarbon spraying, etc.

Contact with us for further inquires.

Tel/WhatsApp: +86 17688923299

E-mail: aisling.huang@aluminum-artist.com

Post time: Aug-31-2023