How much do you know about aluminum pallets for new energy vehicles?

Nowadays, the new energy vehicle industry is developing rapidly. Different from traditional vehicles, new energy vehicles use batteries as power to drive vehicles. The battery tray is a single battery. The module is fixed on the metal shell in the way that is most conducive to thermal management, playing a key role in protecting the normal and safe work of the battery. Its weight also directly affects the load distribution and endurance capacity of electric vehicles. Today, Ruiqifeng will tell you the aluminum battery tray of new energy vehicle.

Several common structural types of aluminum battery tray

Regarding aluminum battery tray, due to its light weight and low melting point, it generally has several forms: die-casting aluminum tray, extruded aluminum alloy frame and aluminum plate splicing and welding tray (shell), molded upper cover.

1. Die cast aluminum tray

The more structural feature is one-time die casting, which reduces the material burning and strength problems caused by the welding of the tray structure, and the overall strength feature is better. The structural characteristics of the tray and frame of this structure are not obvious, but the overall strength can meet the requirements of battery bearing and cutting.

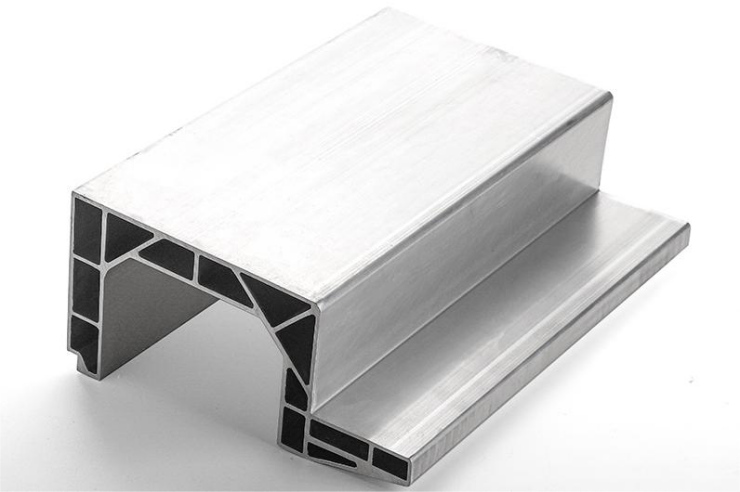

2. Extruded aluminum welded frame structure.

This structure is more common, and it is also a more flexible structure. The welding and processing of different aluminum plates can meet the needs of various energy sizes. At the same time, it is easy to modify the design and adjust the materials used.

3. Frame structure is a structural form of pallet.

The frame structure is more conducive to lightweight, and is more conducive to ensuring the strength of different structures. The structural form of battery aluminum tray also follows the design form of frame structure: the outer frame mainly completes the bearing function of the whole battery system; The inner frame mainly completes the bearing function of sub modules such as modules and water-cooled panels; The middle protective surface of the inner and outer frame mainly completes the isolation and protection of the battery pack from the outside, such as gravel impact, waterproof, thermal insulation, etc.

Post time: Jul-13-2022