Aluminum is one of the most widely used and easiest-to-work metals in the world. When it comes to improving aluminum machining properties, we need to consider a range of factors that can have an impact on the efficiency, quality and cost of the machining process.Improvements in aluminum machining performance can be achieved through a variety of methods, including material selection, optimization of process parameters, and application of tool and lubrication cooling.

Right aluminum material

Choosing the right aluminum material is crucial to improving processing performance. Different types of aluminum have different mechanical properties and processing characteristics. For specific processing requirements, it is very critical to select the appropriate aluminum alloy material. Generally speaking, using pure aluminum or aluminum alloys containing materials with fewer alloying elements can improve processing performance, because these materials usually have better processing plasticity and formability.

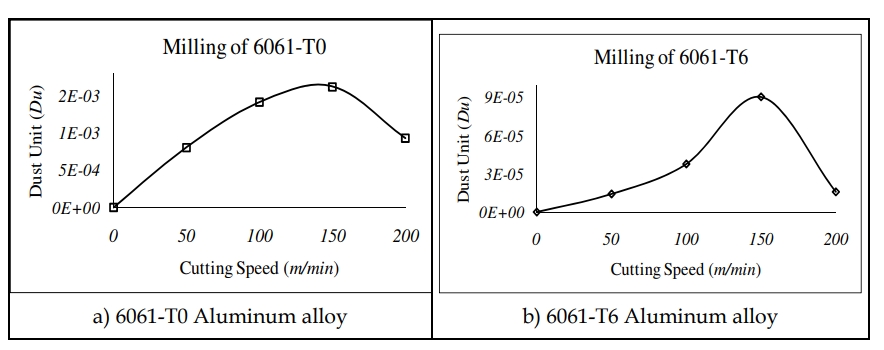

(Experimental (Du) during milling of aluminum alloy 6061-T6 and T0)

Tools and processing parameters

When processing aluminum, it is crucial to control the selection of tools and processing parameters. Using appropriate cutting tools (such as high-speed steel cutting tools or carbide cutting tools) as well as optimized cutting speed, feed speed and cutting depth can effectively reduce cutting forces, reduce tool wear, and improve machined surface quality. In addition, the use of appropriate lubricating coolants can also significantly improve the processing performance of aluminum materials. Lubricating coolant can effectively reduce cutting temperature, reduce friction and wear, and prevent chips from adhering to the surface of the tool and work piece, thereby improving processing quality and extending tool life.

Process monitoring and optimization

Process monitoring and optimization during processing are also a key to improving aluminum processing performance. By real-time monitoring of parameters such as temperature, cutting force, and tool wear during processing, processing parameters can be adjusted in time according to the actual situation to achieve the best processing effect. To sum up, improving the processing performance of aluminum materials requires multiple considerations and comprehensive measures.

By selecting appropriate materials, optimizing processing parameters, using appropriate tools and lubricating coolants, and conducting process monitoring and optimization, the processing efficiency and quality of aluminum can be significantly improved, processing costs reduced, and more benefits brought to industrial production.

Ruiqifeng can provide professional aluminium marching service, feel free to contact us if you have any needs.

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Post time: Feb-01-2024