Electric vehicle is a new increment, its market space is broad.

1. Battery box is a new increment of new energy vehicles

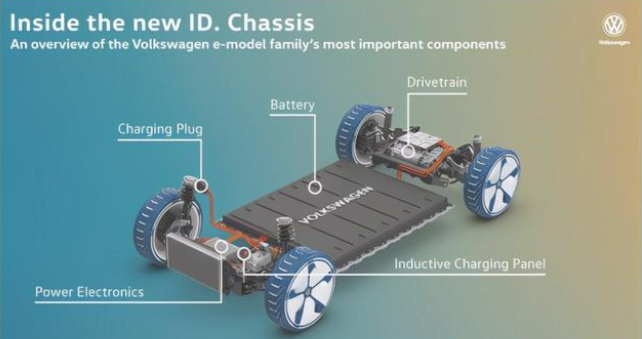

Compared with traditional fuel cars, pure electric cars save the engine, and the powertrain is greatly optimized. The traditional automobile generally adopts the engine in front and the drive in back, which inevitably requires the transmission mechanism to realize the power transmission.

Pure electric vehicles are driven by motors, which can be flexibly adjusted according to the model, thus eliminating the transmission mechanism. The battery shell is the bearing part of the power battery of the new energy vehicle. It is generally installed in the lower part of the car body. It is mainly used to protect the lithium battery from damage when it is impacted and squeezed by the outside force.

2. Battery box is the “skeleton” of battery pack, is an important safety part.

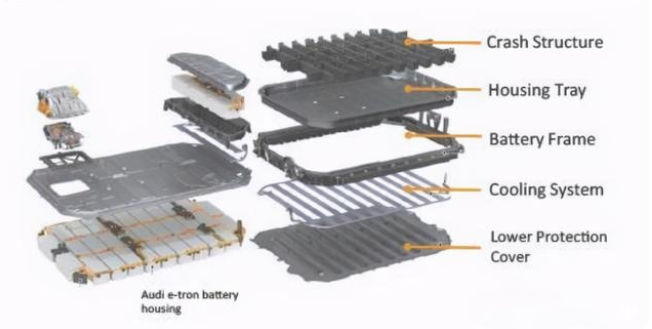

The battery box structure system is mainly composed of battery PACK top cover, tray, various metal supports, end plates and bolts. It can be regarded as the “skeleton” of battery PACK and plays the role of support, mechanical shock resistance, mechanical vibration and environmental protection (waterproof and dustproof).

The box body under the battery box (namely the battery tray) bears the mass of the whole battery pack and its own quality, withstands the external impact, protects the battery module and the battery cell, and is an important safety structure of electric vehicles. The diagram below is a schematic of the Audi E-tron battery box, which uses a grid (or egg-shaped carton) structure to secure and protect the battery modules within the frame and under cover (which provides both protection and chassis integrity).

Note: PACK is the assembling process of lithium battery cells, which can be a single battery or a series and parallel battery module, etc. Battery PACK consists of core, module, electrical system, thermal management system, shell and BMS.

3. Due to the demand of lightweight, battery box materials evolve from steel to aluminum .

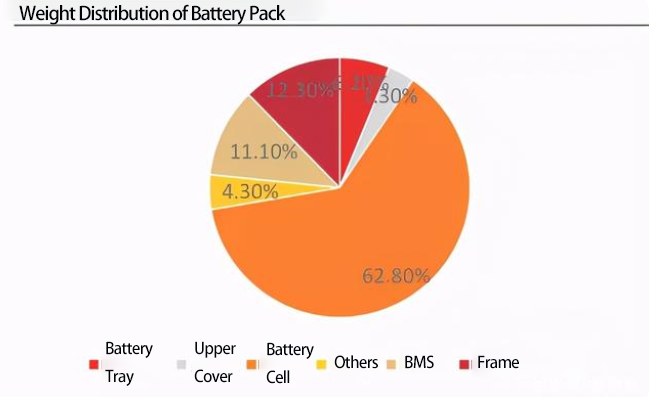

Among the main components of battery Pack, the core body has the largest weight , followed by the box body under Pack, top cover, BMS integrated components, etc. After dismantling the battery Pack of tesla Model3, the weight of the box body accounts for 6.2%, and the weight is 29.5kg. Battery pack shell is the most original power battery pack shell material, generally made of cast steel plate welding, high strength, high rigidity, heavy quality.

Early electric vehicles such as NissanLeaf and Volt adopt steel battery box, which restricts the energy density of battery Pack and affects the endurance of electric vehicles. At present, aluminum alloy battery cases are more commonly used, which greatly reduces the weight compared with steel.

Post time: May-13-2022