What is Aluminum Extrusion?

In recent years, aluminum extrusion is more widely used industrial design and manufacturing. You may hear of this manufacturing process but don’t know how it works. Today we will make you have clear understanding about it though this essay.

1. What is Aluminum Extrusion?

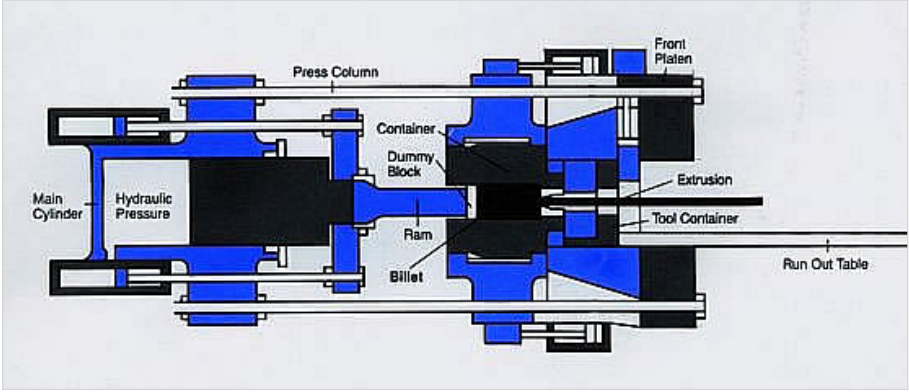

Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile. It can be likened to squeezing toothpaste from a tube. A powerful ram pushes the aluminum through the die and it emerges from the die opening. When it does, it comes out in the same shape as the die and is pulled out along a run out table.

2. Where are aluminum extrusion can be applied?

Aluminum extrusion can be used in many filed, such as windows and doors manufacturing, curtain walls design and manufacturing, automobile, green energy, communication devices, home appliance, infrastructure and so on.

Rui Qifeng can supply various aluminum extrusion products to cater to different use of aluminum profiles. We are cooperating directly with CHALCO, first hand of aluminum resources, will offer you the superior quality with favorable prices.

Please contact with us directly if you have aluminum extrusion requirement.

3. What are the aluminum extrusion processes?

Step 1: Extrusion die drawing design and make extrusion die.

Step 2: Preheating the extrusion die to between 450-500 degrees Celsius and loaded into the extrusion press.

Step 3: Preheating the aluminum rod to between 400-500 degrees Celsius and transfer it to the extrusion press. A lubricant (or release agent) is applied to the aluminum rod and extrusion ram, to prevent the aluminum rod and ram from sticking together.

Step 4: Pushes the aluminum rod into the container and then the aluminum material emerges from the die’s opening in the shape of a fully-formed profile.

Step 5: Extrusions are guided along the run out table and quenched, or uniformly cooled by a water bath or by fans above the table.

Step 6: Extrusions will be sheared by a hot saw to table-length to separate it from the extrusion process.

Step 7: Cooling the extrusion to room temperature and move them to the stretcher and stretch into alignment. Stretching is to correct the natural twisting occurred in the profiles.

Step 8: Cut the extrusion to proper length and come to CNC deep-processing.

Step 9: Aging to T5 or T6 temper.

Step 10: Heat treatment and surface Treatment. Heat treatment can improve the mechanical properties. Surface treatment can enhance appearance ans corrosion protection. Surface treatment includes powder coating, anodized, wood grain, brushed, sandblasting, electrophoresis, polishing and PVDF coating and so on. We will introduce you on surface treatment in separate essay.

Rui Qifeng is a professional vendor who can provide with one-stop aluminum profiles solution. No matter what requirements on aluminum profiles, there are wide range of option for you to meet your specified needs in projects. Welcome further inquires if you are interested.

https://www.aluminum-artist.com/

Jenny.xiao@aluminum-artist.com

Post time: Feb-08-2023