What is surface treatment for aluminum profile?

A surface treatment consists of a coating or a process in which a coating is applied to or in the material. There are various surface treatments available for aluminium, each with its own purposes and practical use, such as to be more aesthetic, better adhesive, or corrosion resistant, etc.

With the continuous improvement of people’s living standards, the requirements for the appearance and color of doors and windows are getting higher and higher, and with the gradual refinement of aluminum processing technology, some complex surface treatments have been flourishing. The aluminum surface treatment processes we often see include electrophoresis, anodizing, powder coating, PVDF coating, wood grain and so on.

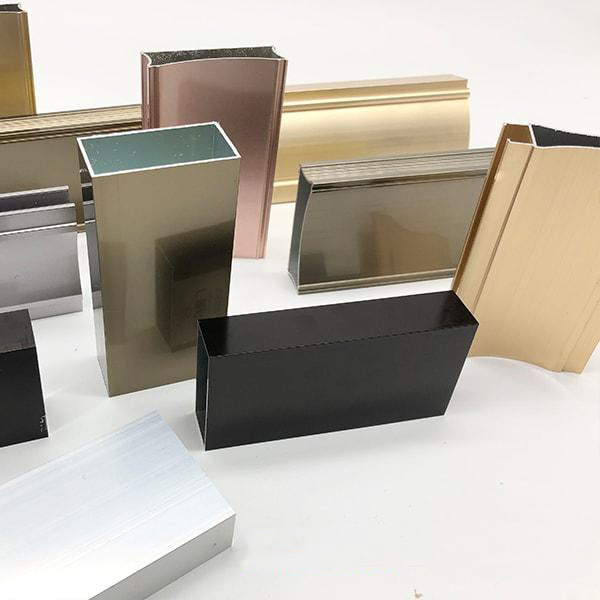

1. Electrophoresis

Electrophoresis is the electrophoretic coating on the cathode and anode. Under the action of voltage, the charged coating ions move to the cathode and interact with the alkalinity generated on the cathode surface to form insoluble substances, which are deposited on the surface of the workpiece. Aluminum profile electrophoresis refers to the process of placing the extruded aluminum alloy in the electrophoresis tank, and forming a dense resin film on the surface after passing through direct current. Electrophoretic aluminum profiles are very bright and have a mirror effect, which also improves corrosion resistance.

Process Flow:

Electrolysis (decomposition) ➤ Electrophoresis (migration, migration) ➤ Electrodeposition (precipitation) ➤ Electroosmosis (dehydration)

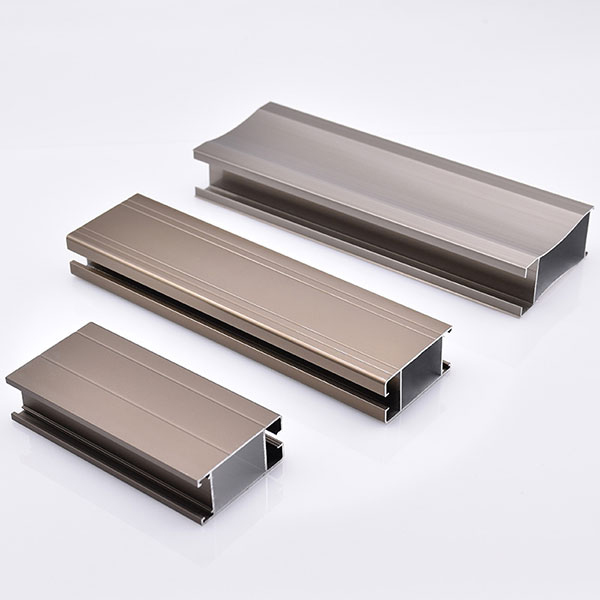

2. Anodizing

Anodized aluminum profiles refer to the process in which aluminum and its alloys form an oxide film on aluminum products (anodes) under the corresponding electrolyte and specific process conditions under the action of an applied current. However, the oxide film formed on the surface of anodized aluminum is different from the general oxide film, and anodized aluminum can be dyed by electrolytic coloring. In order to overcome the defects of aluminum alloy surface hardness, wear resistance, etc., expand the scope of application, and prolong the service life, surface treatment technology has become an indispensable link in the use of aluminum alloys, and anodic oxidation technology is currently the most widely used and most successful. of.

Process Flow:

Degreasing ➤ Chemical Polishing ➤ Acid Corrosion ➤ Stripping Black Film ➤ Anodizing ➤ Pre-Dyeing Treatment ➤ Dyeing ➤ Sealing ➤ Drying

The difference between anodizing and electrophoresis: anodizing is oxidized first and then colored, while electrophoresis is directly colored.

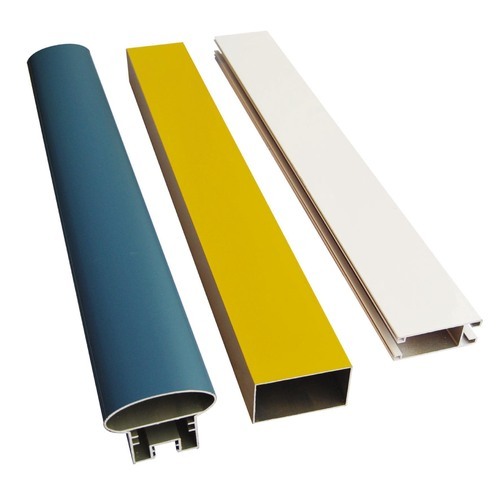

3. Powder coating

Use electrostatic powder spraying equipment to spray the powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating. Various final coatings. The spraying effect is far superior to the spraying process in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance.

Process Flow:

Surface pre-treatment ➤ spraying ➤ baking curing

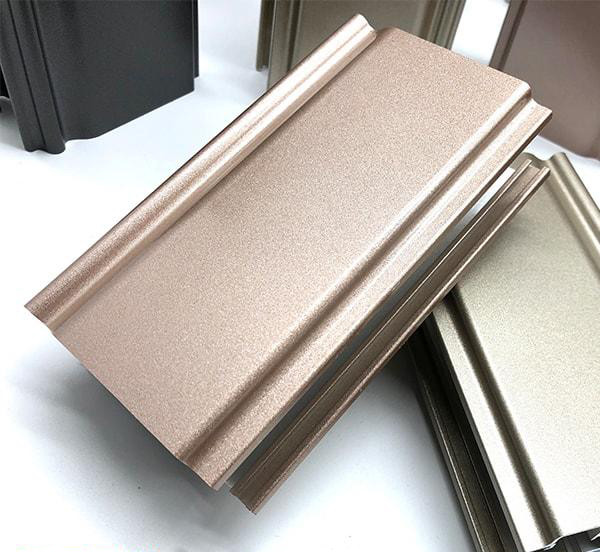

4. PVDF Coating

PVDF Coating is a kind of electrostatic spraying, which is also a liquid spraying method. The fluorocarbon spray coating used is a coating made of baking polyvinylidene fluoride resin as a base material or with metal aluminum powder as a colorant. There are suspended and semi-suspended types. The suspended type is the pre-treatment and spraying of aluminum materials, and the aluminum materials are suspended during the curing process. The high-quality fluorocarbon coating has metallic luster, bright colors and obvious three-dimensional effect.

Process Flow:

Pre-treatment process: degreasing and decontamination of aluminum ➤ washing ➤ alkali washing (degreasing) ➤ washing ➤ pickling ➤ washing ➤ chromizing ➤ washing ➤ pure water washing

Spraying process: spraying primer ➤ topcoat ➤ finishing paint ➤ baking (180-250℃) ➤ quality inspection

The difference between electrostatic powder spraying and fluorocarbon spraying: powder spraying is to use powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powder coating layer. Fluorocarbon spraying is a kind of electrostatic spraying, which is also a liquid spraying method. It is called fluorocarbon spraying, and it is called curium oil in Hong Kong.

5. Wood Grain

Wood grain transfer profile is based on powder spraying or electrophoretic painting, according to the principle of high temperature sublimation heat penetration, through heating and pressure, the wood grain pattern on the transfer paper or transfer film is quickly transferred and penetrated To the profiles that have been sprayed or electrophoresis. The wood-grain profile produced has clear texture, strong three-dimensional effect, and can better reflect the natural feeling of wood grain. It is an ideal energy-saving and environmentally friendly material to replace traditional wood.

Process Flow:

Select substrate ➤ Wrap wood grain printing paper ➤ Cover plastic bag ➤ Vacuum ➤ Baking ➤ Tear off printing paper ➤ Clean the surface

Rui Qifeng can deal with deal with various complex surface treatment for architecture materials. Superior quality and reasonable prices, welcome for further inquiry.

Guangxi Rui QiFeng New Material Co., Ltd.

Address: Pingguo Industrial Zone, Baise City, Guangxi, China

https://www.aluminum-artist.com/

Email : Jenny.xiao@aluminum-artist.com

Post time: Feb-20-2023