What We Can Do In Aluminum Heat Sink Design To Improve Heat Dissipation Performance?

Designing heat sinks is about optimizing the surface area that is in contact with the coolant fluid, or with the air around it.

To improve heat dissipation performance of a heat sink depends on the solution design. Heat sinks are usually air-cooled or liquid-cooled. No matter what you use to cool, the main factors that impact its heat dissipation performance include air or liquid flow and fin design. There are many factors should be taken into account when you come into the design process.

- Surface treatment

- Thermal resistance

- Joining methods

- Materials, including the thermal interface material

- Costs

The majority heat sink in the market are aluminium alloys in the 6-series, primarily the 6060, 6061 and 6063 alloys. Their thermal properties are not as good as those of copper, but an extruded aluminium heat sink weighs about half as much as a copper conductor having the same conductivity, and the aluminium solution does not cost as much, either.

If choosing aluminum alloy as design material, we can improve the heat dissipation performance by:

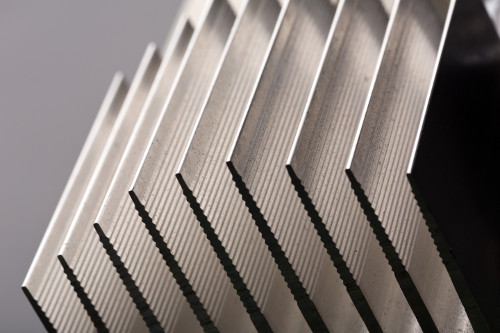

- Increase surface area: increase fins and fin density.

- Improve the diffuse emission rate: apply powder coating or sandblasting surface treatment to improve roughness.

- Improve the heat transfer coefficient: add a fan to increase the speed of the wind on the surface of the heat sink.

To know more about aluminum heat sink heat dissipation performance, welcome further inquiries with Rui Qifeng.

Post time: Mar-09-2023