As electric vehicles (EVs) gain popularity worldwide, the demand for lightweight and sturdy materials in their production is increasing. Aluminum extrusion alloys have emerged as a game-changer in the automotive industry, as they offer numerous benefits such as enhanced structural strength, weight reduction, and increased energy efficiency. In this article, we will explore some of the innovative uses of aluminum extrusion alloys in EVs, particularly in battery trays, guardrails, and cooling plate trays.

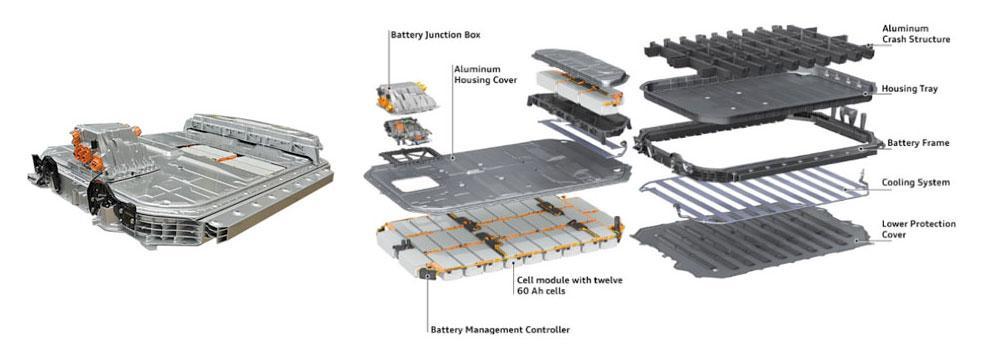

Battery Tray and Guardrail

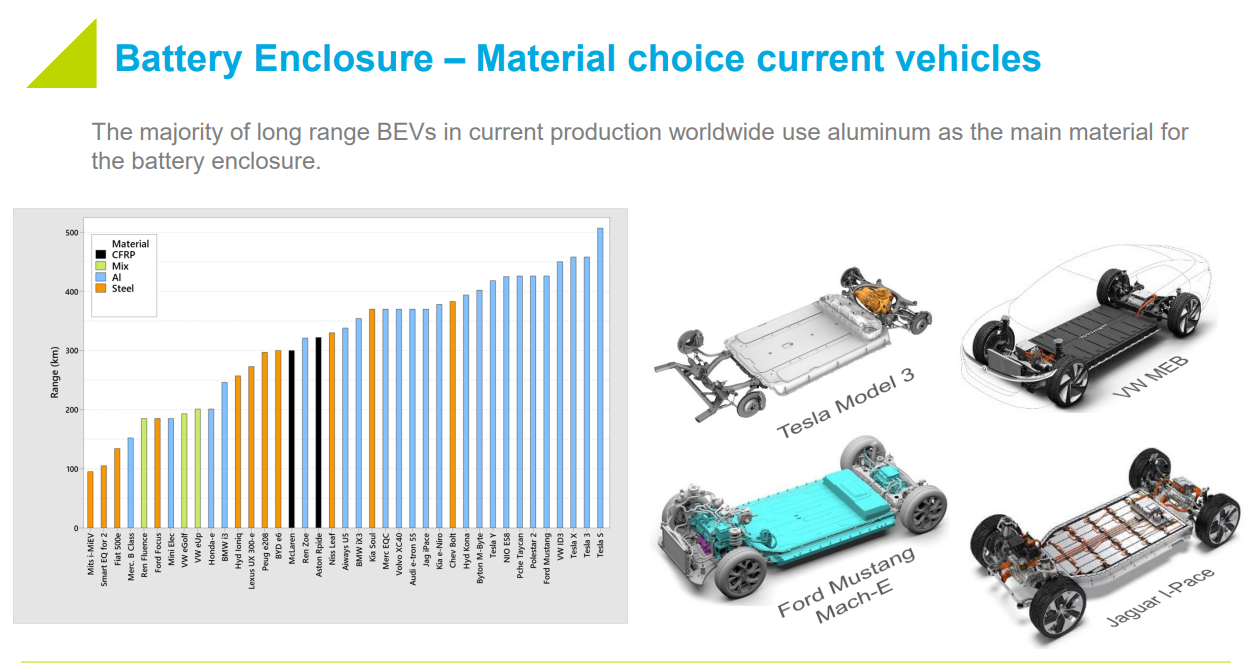

The primary issue for the battery tray is the material, which must have excellent comprehensive performance and an acceptable and reasonable price. Under current conditions, aluminum is the most desirable, superior to steel and carbon fiber reinforced plastic matrix composites (CFRP).

Almost all original vehicle equipment manufacturing companies use aluminum extrusions to manufacture battery trays, such as BMW, Audi Group, Volvo, etc. At the same time, some companies are very interested in Tesla’s all-aluminum skateboard battery tray made of extruded aluminum, and have followed suit, such as BMW’s i20 EVs car tray, Audi’s e-tron electric car tray, Pallets for Daimler’s EQ range of electric vehicles and more. Audi’s original trays were made of die-cast aluminum alloy parts, but have now been replaced with extruded aluminum. Its battery trays for BEVs and PHEVs are also made of extruded aluminum.

It is worth noting that some companies that used to make pallets from steel are now switching to aluminum. For example, Nissan Motor Company’s Leaf EV electric vehicle used to use steel to make battery trays, but switched to extruded aluminum in 2018; Volkswagen has always had a soft spot for steel battery trays, but its new BEV electric vehicle battery trays also conform to This trend led to the use of extruded aluminum; AkelMittal had decided to use high-strength steel for the body structure of the Tesla Model 3 car, but later found that the steel structure body did not match the connection of the aluminum battery tray , so it was changed to an aluminum alloy body.

Innovative aluminum cooling slab tray

In 2018, Constellium’s Brunel Advanced Solidification Technology Center invented a new tray design called “cold aluminum”, which has a strong cooling efficiency for battery packs. With this design, there is no need for friction stir welding connections anymore. Tests have shown that the cooling plate is tightly connected and will not leak, and at the same time, the connection is simple and quick. When experimenting with the mixed cooling method, a very satisfactory cooling effect was obtained, and the temperature deviation was only ±2 °C. Therefore, the service life of the battery pack is extended, and the safety performance is improved. Some parts of the tray are manufactured from extruded and bent aluminum, without drilling or welding, and the mass of the new design dropped by 15%.

Contact with us for further inquires.

Tel/WhatsApp: +86 17688923299

E-mail: aisling.huang@aluminum-artist.com

Post time: Aug-23-2023

Source: Constellium

Source: Constellium